Portfolio expansion of laser-transferable PVD coatings

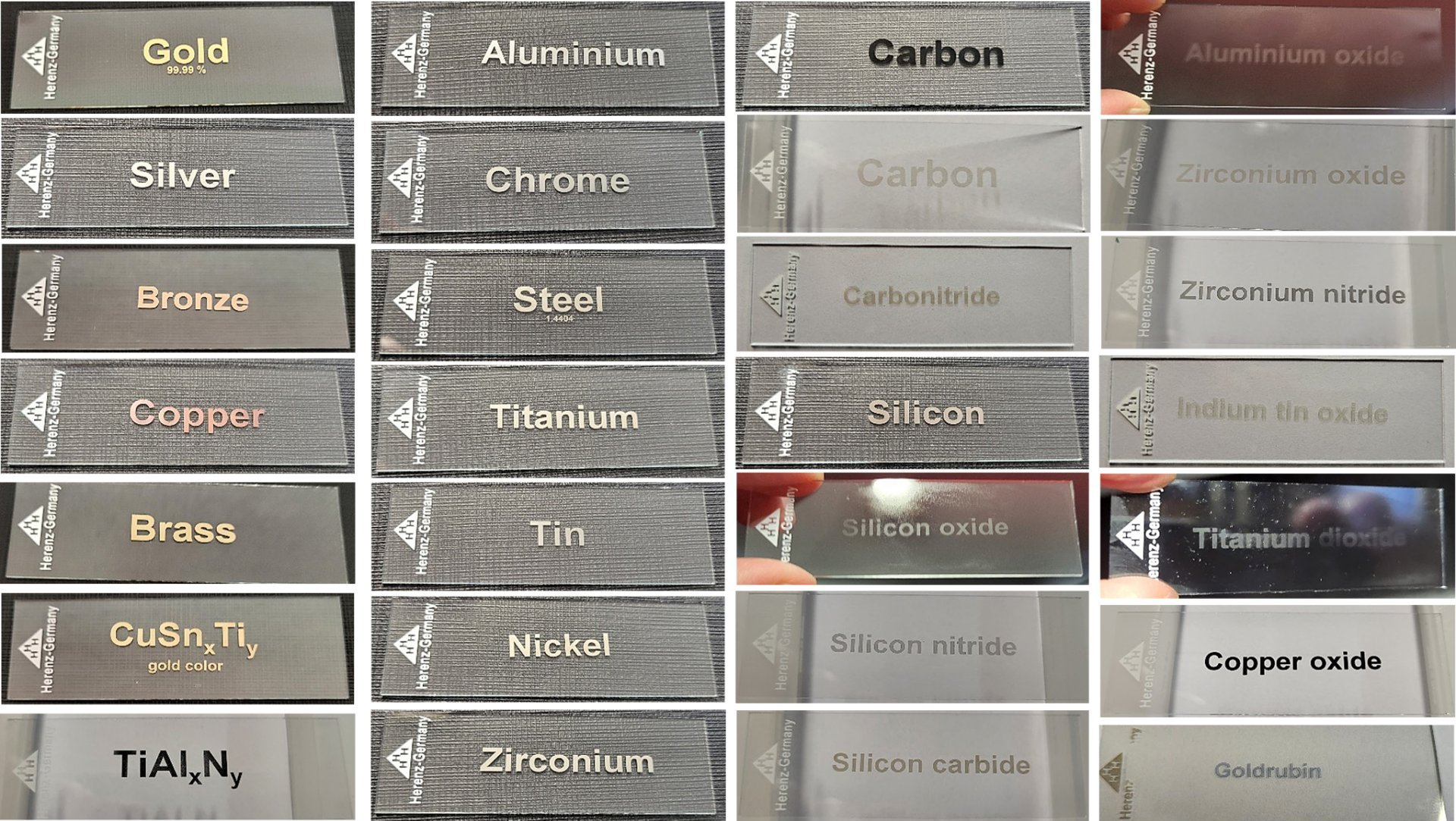

We are delighted that we have been able to expand our portfolio of laser-transferable PVD coatings once again: In addition to metals and alloys, we have now added many oxides, nitrides and carbides.

A selection of these additive laser markings from the respective materials on glass can be seen below.

In order to make the selective transfer of the transparent PVD layers onto glass surfaces visible at all, we have either selected a layer thickness that shows a (weak) interference color - if they have an extinction - or we have "adjusted" their surface structure via the laser parameters so that transparent layers without extinction such as SiO2 or Al2O3 become visible after moistening or breathing on them.

The advantage of "laser deposition" of these layers compared to sputtering or vapor deposition in a vacuum is that these "laser layers" can be applied selectively and quickly even to sensitive product surfaces - and also have significantly better adhesion and abrasion resistance. All you need is a marking laser and one of our ARA-LT® laser foils.

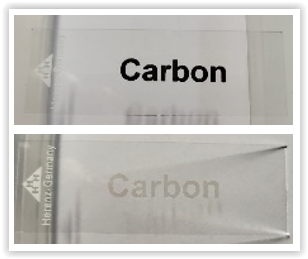

What's more, these "laser layers" can also be modified during the transfer process: for example, the hybrid-orbital formation can only be influenced by suitably selected laser parameter settings when transferring carbon: The figure below shows a black carbon inscription (predominantly sp2-hybridization) and a nearly transparent carbon layer (predominantly sp3-hybridization).

Further examples of the functionalization of laser-transferable PVD coatings will be presented shortly.