The laser-induced PVD layer transfer ARA-LT®

A very efficient method for marking or labeling is transferring an inorganic material from a carrier film to the product surface with a laser beam - in a very small thickness and also only where necessary.

A very efficient method for marking or labeling is transferring an inorganic material from a carrier film to the product surface with a laser beam - in a very small thickness and also only where necessary. Almost all metals, alloys and even ceramic hard materials can be used for such additive laser marking.

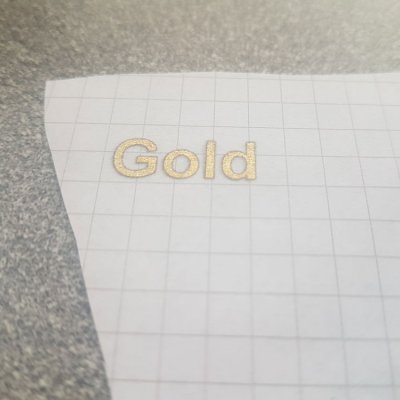

In this way, the finest structures, beautiful logos or even large areas can be lasered onto almost any product surface quickly and in the highest quality. For example, a layer of fine gold (i.e. 99.99% pure) - can be applied to steel, glass (Fig. 1) ceramics, plastics or even paper (Fig. 2) - without affecting the product surface.

In the case of laser-transparent materials, even their inner or back surfaces can be coated in this way.

Another exceptional feature of ARA-LT® technology is its excellent abrasion resistance and high temperature resistance.

Fig. 3 shows an electrical circuit lasered onto a ceramic tile at a temperature of 1000 °C - which still functions afterwards. In Fig. 4, an unsuccessful attempt was made to remove an ARA-LT® marking from an enamel surface using steel wool.

Besides single layers, almost any PVD material and layer combinations can be realized.

... and we can also do beautiful colors - but more about that in a week!