Facts and figures

- Foundation of Ara-Coatings GmbH & Co. KG in October 2006 in Erlangen

- The company moves to Nordhorn in July 2021

- Specialized in non-destructive markings and coatings based on PVD (“Physical Vapor Deposition”) with standard marking lasers

Our philosophy:

We are currently living in a time of great change.

The subject of the environment in particular will occupy us not only now, but also in the future, to an extent that has never been the case before.

We at Ara-Coatings are convinced that - in addition to a general heightening of environmental awareness - it is useful and necessary to develop further technically in order to be able to successfully combat the growing environmental problems.

It is a great advantage that we can benefit from a technological basis that generations before us have developed and that now offers us exactly the possibilities to realize our ideas.

But what exactly are our ideas?

First of all, we considered that we would like to manufacture products that are both ecologically harmless and economically profitable. In addition, the products should consist of materials that pollute the environment as little as possible, occur in large quantities on earth and are available worldwide.

In order to come as close as possible to this concept of an “egg-laying woolly milk sow”, we developed the idea of combining the physical vapor deposition (“PVD”) coating process with laser technology.

This enabled us to develop products in the form of laser foils with which extremely thin, but multifunctional, inorganic layers can be applied to surfaces - only and precisely where they are needed.

You can get a “feel for” how big the material savings are if you look at the lettering on everyday objects, for example: Usually these are printed on and the lettering is then at least 0.02 mm thick. The thickness of “our” lasered PVD layers are a hundred or even a thousand times thinner!

At the same time, the optical quality and robustness are much better.

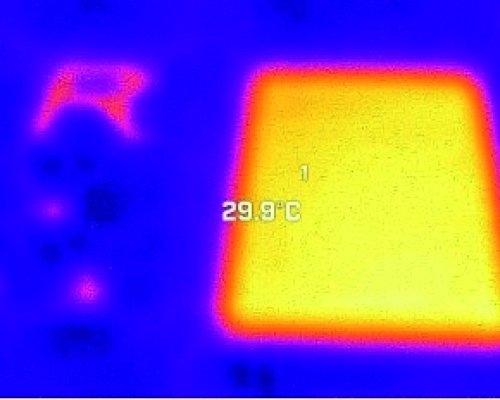

In the course of our work with our new technology of “laser-induced PVD coatings”, we were also surprised by the fact that not only metals, semiconductors and ceramic layers can be transferred with standard marking lasers, but that these layer materials are also “energetically” charged and this results in extraordinary properties: For example, we can now produce large-area layers with permanently strong catalytic effectiveness from titanium and silicon, porous SiO₂ with a low refractive index or superhydrophilic or hydrophobic surfaces.

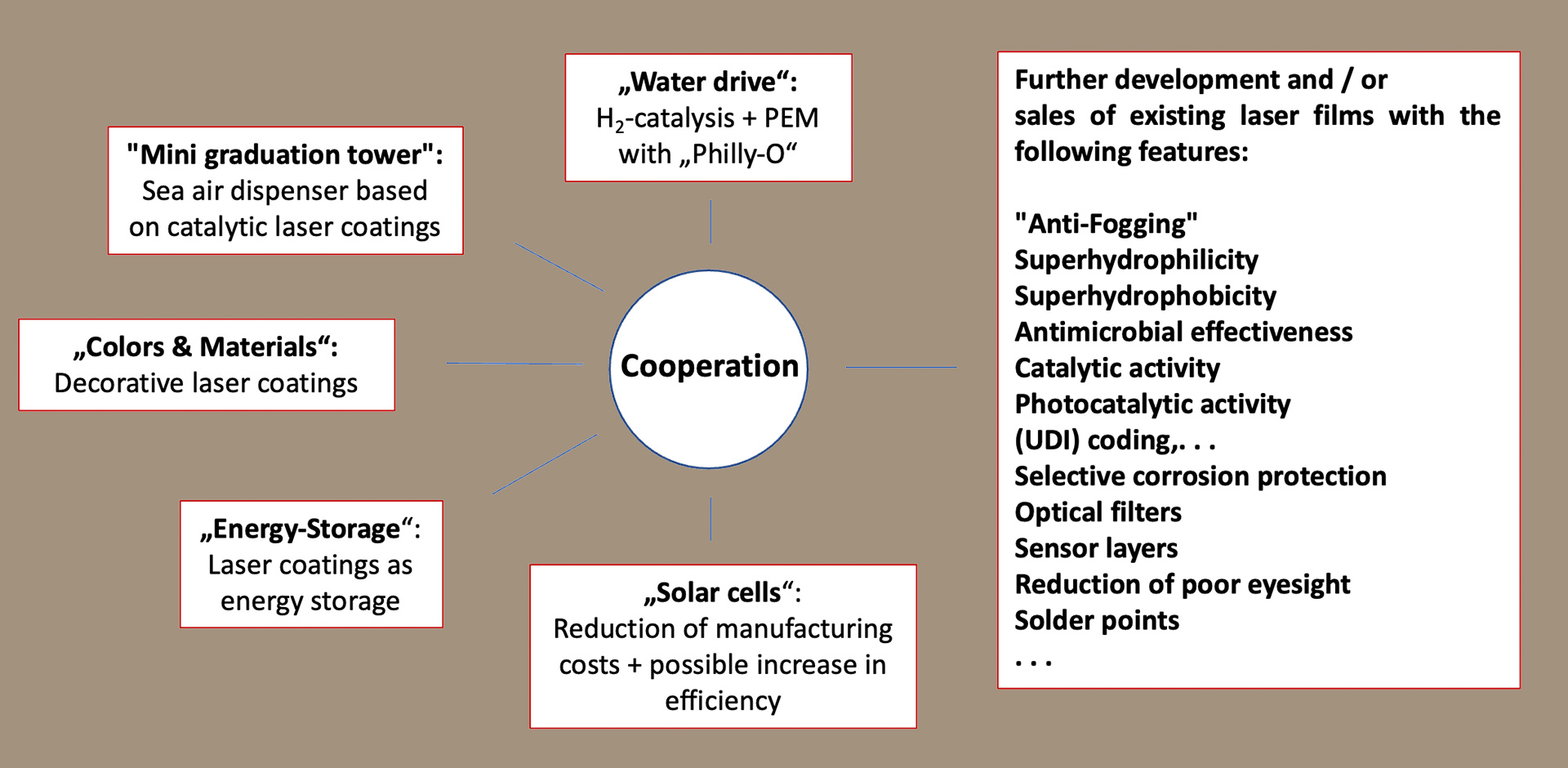

This of course results in exciting application possibilities in areas such as the generation and use of hydrogen, battery or solar cell production or, in general, for optical purposes.

Because these topics are very complex and cannot be handled by Ara-Coatings alone, we are looking for suitable cooperation or sales partners for the relevant fields of application.

News

Read here current information about our activities and developments