PVD layers transferred with a laser show remarkable "nano effects", part 2

In recent months we have been intensively researching new layer properties that are made possible by our innovative laser-induced PVD coating technology ARA-LT®. We look forward to presenting the exciting results of our research to you.

Part 2: Permanent catalytic activity and a “capillary effect without capillaries” of laser-applied, porous silicon layers

Again starting from one and the same silicon laser foil, silicon layers can be produced on product surfaces by means of laser-induced transfer, which are permanently catalytically active. This can be demonstrated, for example, with methylene blue, which discolors immediately after application - and this many times in a row.

Another effect that can be induced on the porous "silicon laser layers" is the spontaneous formation of many bubbles after the silicon layers are wetted with distilled water: these bubbles appear immediately after contact with water, grow larger and - disappear again. The photo "Blistering" illustrates this process, which can be repeated almost any number of times and also takes place in complete darkness. Since no other material is involved apart from silicon and distilled water and the room temperature remains unchanged (even falling slightly), it must be assumed that water on the silicon surface decomposes into hydrogen and oxygen. However, there is still no proof of this.

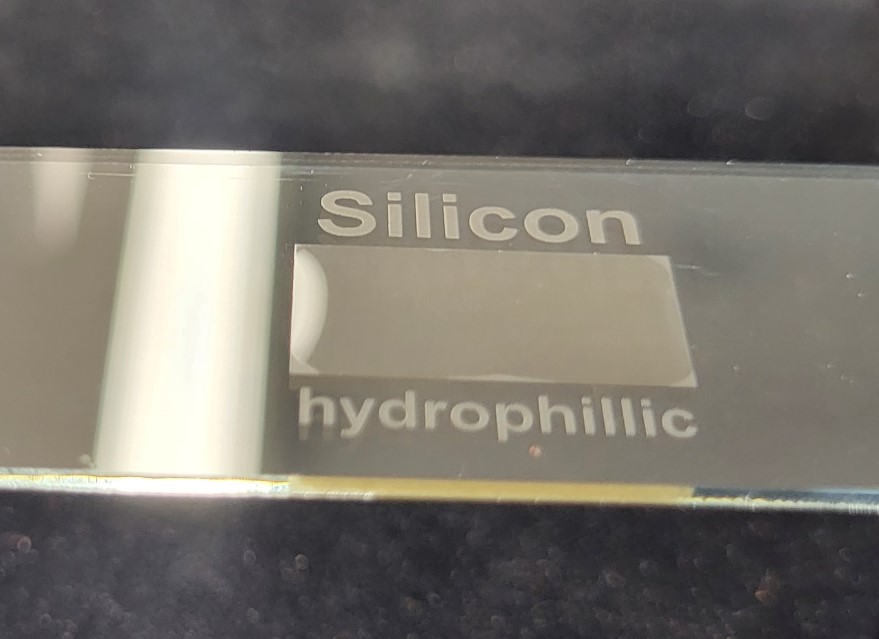

If the laser parameters for the silicon layer transfer are set slightly differently, then either a superhydrophilic surface can be generated or an extremely "absorbent" silicon layer - or both together: In the following photo, a very thin layer was created, only a few nanometers thick and therefore almost transparent silicon layer exposed to water. The water completely wets the layer surface (the white bar in the photos is the overhead lighting reflected in the slides).

In contrast to this, the silicon layer can also be applied so thick and porous that no water film forms, but the water quickly seeps into the layer and spreads out laterally under the layer surface. A snapshot of this can be seen in the photo below: After a drop of water has been applied to the rectangular silicon layer on the right, it immediately spreads, seeps into the layer and spreads to the left, as in the convex, dark area can be seen. It is also particularly exciting that in this way water can be made to flow uphill above the silicon layer, as was shown in a short film on LinkedIn. Of course, even thin “wires” can be easily generated in this way.SEM images of this layer show a periodic pattern consisting of circles (laser spots) that are "framed" by needle-like structures.

Please feel free to contact us if you have any questions, if you are interested in using one of the currently available laser foils in your company or if you would like to start a development project for a new application with us.